On 23rd March 2021, MountainBlog editorial staff followed the Sustainability Conference organized online by Polartec, moderated by Charles Ross (Lecturer at the Royal College of Art, School of Fashion and Textiles), and with an international panel of experts:

- Eva Karlsson, (CEO, Houdini Sportswear)

- Morton Barlaz (Head of the Department of Civil, Construction and Environmental Engineering at North Carolina State University);

- Jeff Strahan (Director of Research, Compliance and Sustainability, Milliken & Company);

- Bruno De Wilde (Laboratory Manager of Organic Waste Systems (OWS), Ghent, Belgium).

Steve Layton, President at Polartec, introduced the conference recalling the Polartec four product mandates:

- Great durability in our products: “Longevity is one of those areas that doesn’t get talked about enough. If you can expect long-lasting, highly durable products, you don’t need to worry about the end of life”.

- Leveraging Milliken’s chemistry and research: “Polartec has made significant breakthroughs in the water repellence side and is going PFC free”.

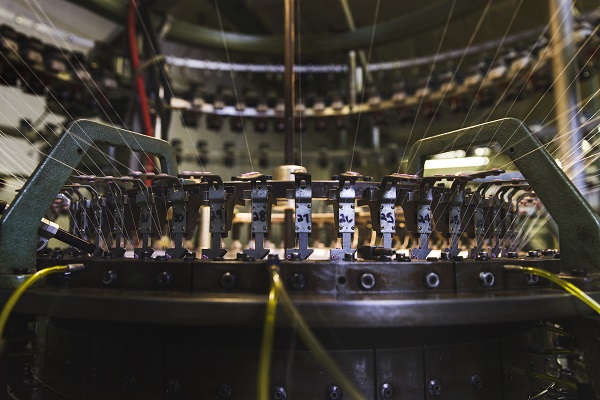

- Impact of fiber shedding: “This is about how we construct fabrics and about what fibers we use in performance fabrics”.

- Total circularity: “Using recycled inputs to make a product that has a long life and is durable – That can be recycled into raw materials – That can be made into a new product for the same use”.

Introducing the panel of experts, Charles Ross drew attention to four roles that clothing needs to perform to be successful garments:

Eva Karlsson spoke about how Houdini, already in 2001, began to move from linear to circular thinking: “We found that it was dangerous for us to stay focused on climate and carbon. We needed to understand how we impact the land system, oceans, and climates; have a holistic and systemic insight”.

As a key point, she outlined the Houdini’s Design checklist:

- Does this product deserve to exist?

- Will it last?

- Is it versatile?

- Will it age with beauty?

- Nothing added that isn’t needed

- Is it fit for sharing, remaking and reselling?

- Does it have a next life solution?

As another very interesting tool, she presented a formula that Houdini developed a couple of years ago to recognize the impact from the production:

P x V + L = I

- P = Production – the process and the design

- V = Volumes

- L = Lifestyle – “that we portray and strengthen through our brand”

- I= Impact

In conclusion, she said: “In 2022 we are aiming to be 100% circular. We are looking at connecting our products with Digital ID to make sure that we help our end users follow our garments all the way through a long lifetime and into the recycling process”.

The “bigger message” of Dr.Morton Barlaz – an expert about biodegradability – was this: When we ask, are we making the best possible material or is our material sustainable, I think it’s crucial that we talk about three phases of the entire life cycle of a material:

- Manufacturing the material

- How that material is used

- What we do with it at end of life.

The key concept here is that “we are not making things to dispose of them but to use them”. In fact, biodegradability is not always desirable:

“If I’m trying to solve a litter problem, biodegradability is good. But if I’m considering sustainability then it may or may not be good” – like in the example of the landfills, where there’s the problem of methane emissions from biodegradation processes.

Jeff Strahan spoke about the importance of Life Cycle Analysis to recognize the role of textile fiber in different categories of impact:

“Regarding climate change, cotton ranks the lowest and nylon is the worst offender. Cotton has the best performance because it’s a plant and as it grows it sucks up CO2. But we can’t just look at one category. If you look at land-use cotton goes from the lowest impact to the highest (you need land to grow those plants) and Nylon ranks as the lowest”.

He believes “LCA will continue to improve and become commonplace“, and “business and policy decisions will be driven by science and those facts and data will drive what we do”.

Bruno De Wilde focused on misconceptions with biodegradation:

- What is biodegradation really?

- How can it be different in different environments (not unilateral answer)?

- Fabrics – we have seen the distinction between fast biodegradation and others where you need a slow one.

He also distinguished between biodegradation vs disintegration: “disintegration is when it visually disappears and biodegradation where it changes to water, biomass, and CO2. The only true parameter is CO2 production, that’s why all the standards are focused on measuring that”.

He remarked the fact that the biodegradation process can be different depending on the environment: “There’s an order: compost is the most aggressive environment; soil second. Freshwater, marine, and landfill are the weakest regarding biodegradation”. (Due to different variables, like temperature, and the more or less presence of fungi).

He finally spoke about the trends that we see in biodegradation on a standardization level and legislative levels.

Andrea Bianchi – MountainBlog Network Publisher